In addition to subverting traditional manufacturing, 3D printing will also improve sustainability by using non petrochemical materials. New materials will be cheaper and easier to procure, which will reduce manufacturing costs. These lower costs will also affect the cost of material storage, transportation, and transportation systems.

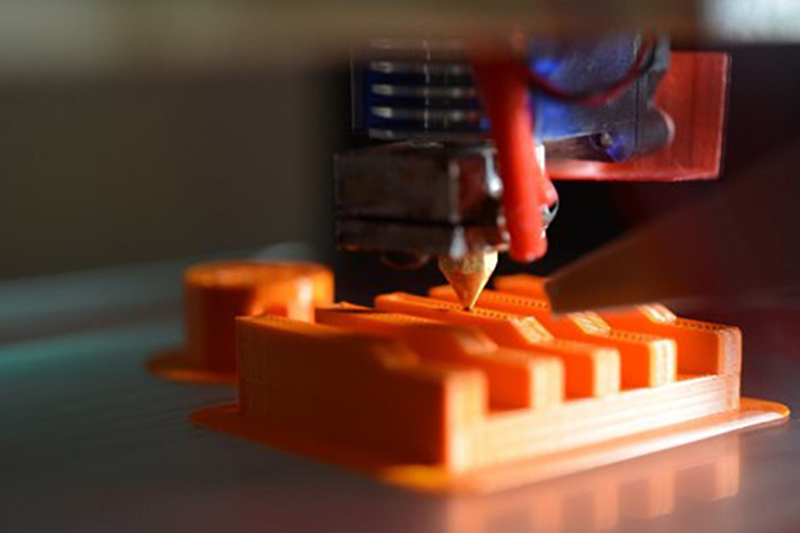

What is additive manufacturing?

Additive manufacturing is the process of manufacturing objects by stacking materials layer by layer (usually plastic or metal powder). These goals can actually be anything. As long as 3D models can be designed in the software, they can be printed out.

Why is additive manufacturing disruptive?

In traditional manufacturing, there are several steps involved in conceptualizing, designing, and developing products. Firstly, designers need to design blueprints. Next, the organization needs to contact factories and material suppliers. Then, the factory will produce a sample for the equipment and return it to the organization (this may take several weeks, especially if the factory is overseas). If adjustments need to be made to the sample, this process must be repeated to turn weeks into months. Once it's time for large-scale production, factory managers will supervise the people or robots on the assembly line to complete the production. Then transport the finished product back to the organization.

Compare it with additive manufacturing. Although designers still need to design blueprints. However, there is no need to contact the factory for sample production or large-scale production, both can be completed internally using several 3D printers with the help of plastic or metal powder distributors. The time required for the product to go from concept to market is only a small fraction of the past.

For small organizations without production capacity, factories will always exist for large-scale production, but the ability to produce samples without outsourcing can save the company a lot of time.

Sustainable production

One of the best aspects of 3D printing is its incredible diversity in the materials we can choose from. This means that it is possible to transition from unsustainable manufacturing processes to more sustainable manufacturing processes without updating equipment - something that businesses need to do as they face increasing pressure.

At present, the biggest environmental obstacle in metal additive manufacturing is the powder atomization process. The two main forms of atomization are gas and plasma, which consume a large amount of energy and cause a huge impact on environmental friendliness.

Therefore, new processes are currently being developed to address this challenge. For example, variants of microwave based plasma atomization can recover used materials with nearly 100% yield, while using less energy than gas or plasma atomization. Resin materials are also being developed to help safely store and recover metal condensates, reducing the waste we generate. We can even make recycled plastic filaments at home.

All of these technologies enable us to utilize domestic waste piles without relying on foreign production and extraction. What we get is a sustainable production cycle, where companies purchase materials made from additive manufacturing waste, 3D print their products, and then sell their new waste back to powder recycling producers.

In addition, bio based materials such as PA11 made from castor seeds and castor oil are becoming increasingly common. This means less metal mining and plastic manufacturing. In the future, 3D printing will use a variety of materials.

Intelligent manufacturing

The current emerging trend includes the customization of additive manufacturing in organizational workflows. At this stage of development, companies are still striving to understand how to integrate 3D printing with existing technologies. When problems occur without manual monitoring, machine learning can play a role in correcting errors and errors in the production process. This kind of "intelligent manufacturing" will significantly improve production efficiency, scale, and the process for designing cross industry products.

Medical applications

Looking into the future, we will see more integration of 3D printing into the biopharmaceutical industry. In fact, this is already happening, and being able to print patient specific implants and devices (called bioprinting) is no longer just a dream, it is also the next frontier. The new materials under development can help manage drugs, manufacture biological tissues, and ultimately print implantable organs.

The future of 3D printing is bright

3D printing is the future. A future that has a profound impact on sustainability and eliminating waste. The development speed of 3D printing or additive manufacturing is astonishing. Initially just printing simple 3D figurines, it has now become a new breakthrough technology used across industries and academia.

Nowadays, we can see the formation of new materials and atomization processes that are beneficial to the Earth's environment. The medical department is using 3D printing to produce patient specific implants and devices. Sample production will be able to be completed internally, rather than relying on overseas factories. The more progress we make, the clearer it becomes that the future is built on additive manufacturing.