Two photon (or multi photon) lithography technology can achieve polymer nanostructures with almost any geometric shape. Two photon corrosion inhibitors typically use photoinitiators that absorb photons to form reactive species (such as free radicals) that initiate polymerization. High performance two-photon initiators can greatly enhance printing speed and resolution. At present, almost all two-photon initiators are organic molecules and cannot improve the performance and structural complexity of the final printed product. In addition, each organic photoinitiator is usually only effective for a single type of monomer. Composite nanostructures can be printed by adding metal ions or inorganic particles to existing two-photon corrosion inhibitors. But this strategy is ineffective for complex mechanical nanogrids, as the performance of the material is affected when there are small structural defects. Uncontrollable reduction of metal ions and particle growth lead to structural defects and a decrease in characteristic quality, and aggregated particles can interfere with the propagation of light. Therefore, high-quality 3D nanoprinting is mostly limited to simplicity and currently poses challenges for the manufacturing of complex systems.

Based on the above challenges, Professor Wendy Gu's research group at Stanford University reported a strategy for rapidly printing complex structured nanocomposites using metal nanoclusters. These ultra small, quantum confined nanoclusters can serve as highly sensitive two-photon initiators, as well as precursors for mechanical reinforcement and nanoscale pore forming agents. Print nanocomposites with complex 3D architectures, as well as structures with adjustable, layered, and anisotropic nanoporosity. Nanocluster polymer nanolattices have high specific strength, energy absorption, deformability, and recoverability. This framework provides a generalizable and universal method for the use of photoactive nanomaterials in additive manufacturing of complex systems with urgent mechanical properties. The related achievements were published in Science under the title "Mechanical nanolatices printed using nanocluster based photos". The first authors are Qi Li and John Kulikowski.

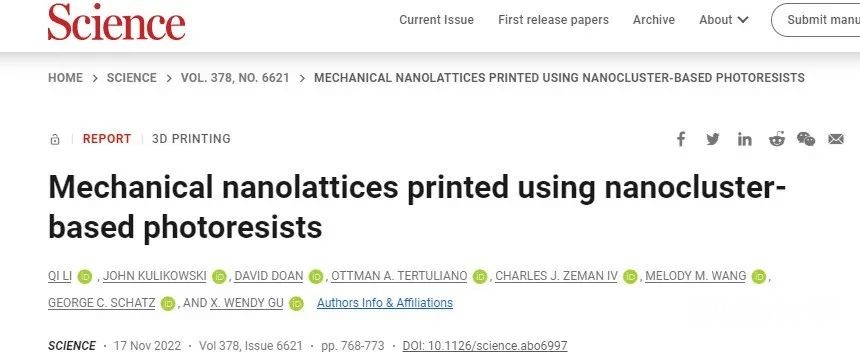

The photoresist based on nanoclusters consists only of metal nanoclusters, monomers or epoxy monomers (Figure 1A), and solvents. The author found that nanoclusters can serve as photoinitiators for free radical polymerization, photoacid generators for cationic polymerization, and photosensitizers for promoting the formation of singlet oxygen to induce protein cross-linking (Figure 1B). In this study, Ag28Pt nanoclusters and rod-shaped Au25 nanoclusters were selected as two-photon initiators. These two nanoclusters have stable and long-lived S1 excited states, which facilitate the generation of free radicals or other active species (Figure 1C). This method is different from organic two-photon initiators, which have a shorter S1 excited state lifetime. In organic two-photon initiators, crossing the triplet state between systems is usually necessary to generate reactive species, which may reduce the overall photoinitiation efficiency (Figure 1C, right). More importantly, compared to molecular photoinitiators that typically have limited cleavage pathways, nanoclusters provide more types of bond cleavage (Figure 1C, left), which leads to increased reactivity with different reagents.

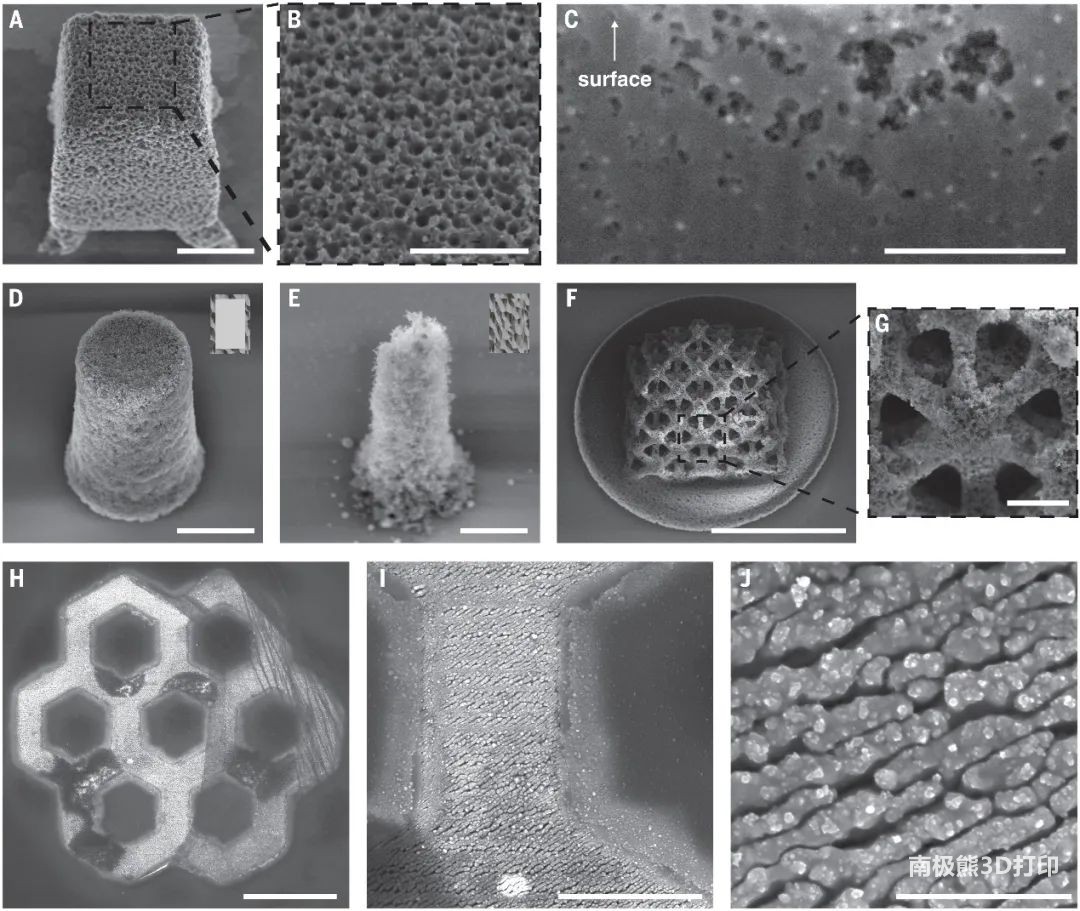

Next, the author evaluated the printing ability of nanoclusters acrylic photoresists. For 5wt% Ag28Pt photoresist, a square structure can be fabricated at laser power as low as 4mV and scanning speed as high as 100mm/s (Figure 1D). Under conditions of laser power as low as 2.5 mW and scanning speed as high as 150 mm/s, 8wt% Au25 photoresist also exhibited similar performance (Figure 1D). The open table, octagonal lattice, and Schwarz original (SP) lattice made using Ag28Pt and Au25 photoresist are shown in Figure 1E-I. Figure 1E shows that independent 3D features can be as small as 400 nanometers. The minimum support rod thickness of an octagonal lattice is 1.27 μ M (Figure 1G). The minimum wall thickness of the SP lattice is 850nm (Figure 1I).

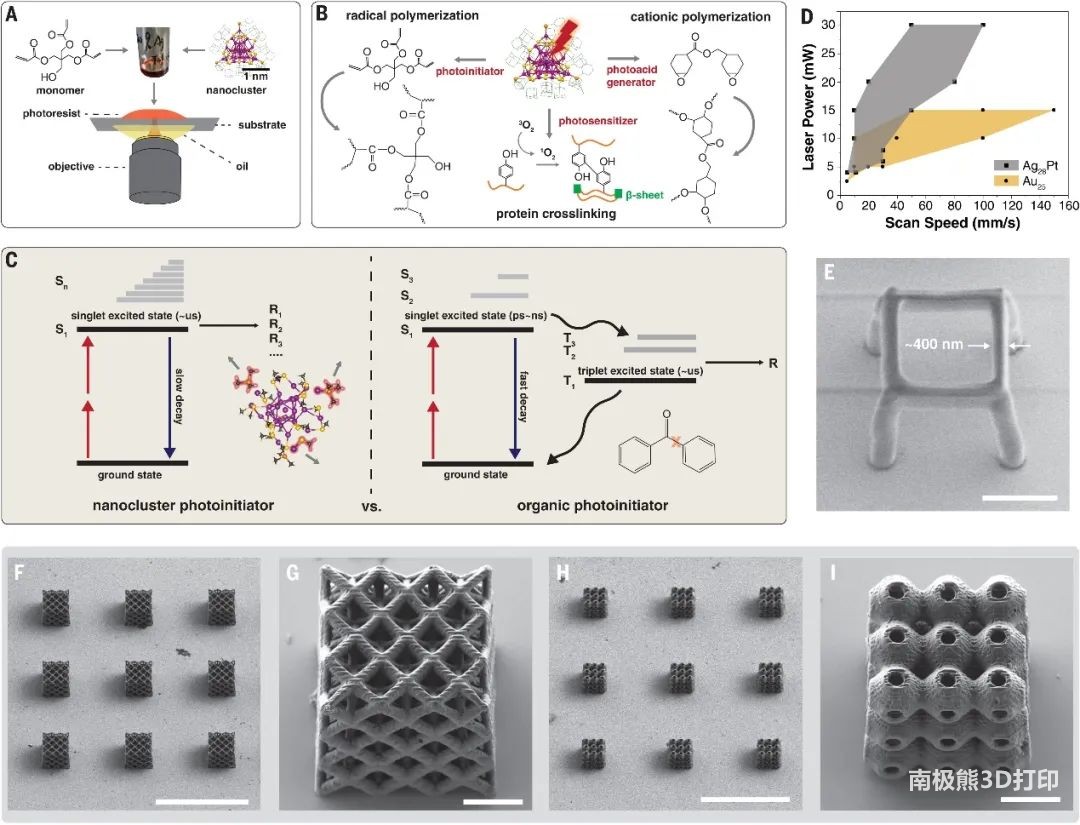

The mechanical properties of printed nanoclusters polymer structures were evaluated using in-situ SEM compression testing (Figure 2). Using 8wt% Au25 PETA photoresist to manufacture a radius of 2.5 μ m. Height of 10 μ The cylindrical pillar of m. The cyclic test showed that the sample had a 70% recovery rate when loaded to 30% strain (Figure 2A). High strength, stiffness, and strain hardening result in energy absorption reaching 110MJ/m3 before the initial crack formation. This mechanical behavior is also evident in honeycomb structures made with 10 wt% Ag28Pt PETA photoresist (Figure 2B). The height of the honeycomb is 8.2 μ m. Cell edge length is 2.6 μ m. The wall thickness is 800nm (Figure 2C). This results in a density of 0.56g/cm2 and a relative density of~48%. The compressive stress-strain response shows a linear region, followed by a significant yield pressure at 22.1 megapascals (Figure 2B). The Octet and Schwarz primary (SP) lattices are made of 8wt% Au25 photoresist. These structures exhibit high energy absorption before densification. The energy absorption capacity of Octet lattice with relative densities of 19% and 27%, and SP lattice with relative densities of 20% and 26%, respectively, reached 7.6 MJ/m3 and 9.7 MJ/m3. In situ SEM compression testing showed that this optimal performance is due to the characteristic material properties of nanoclusters polymer composites (Figure 2D-K).

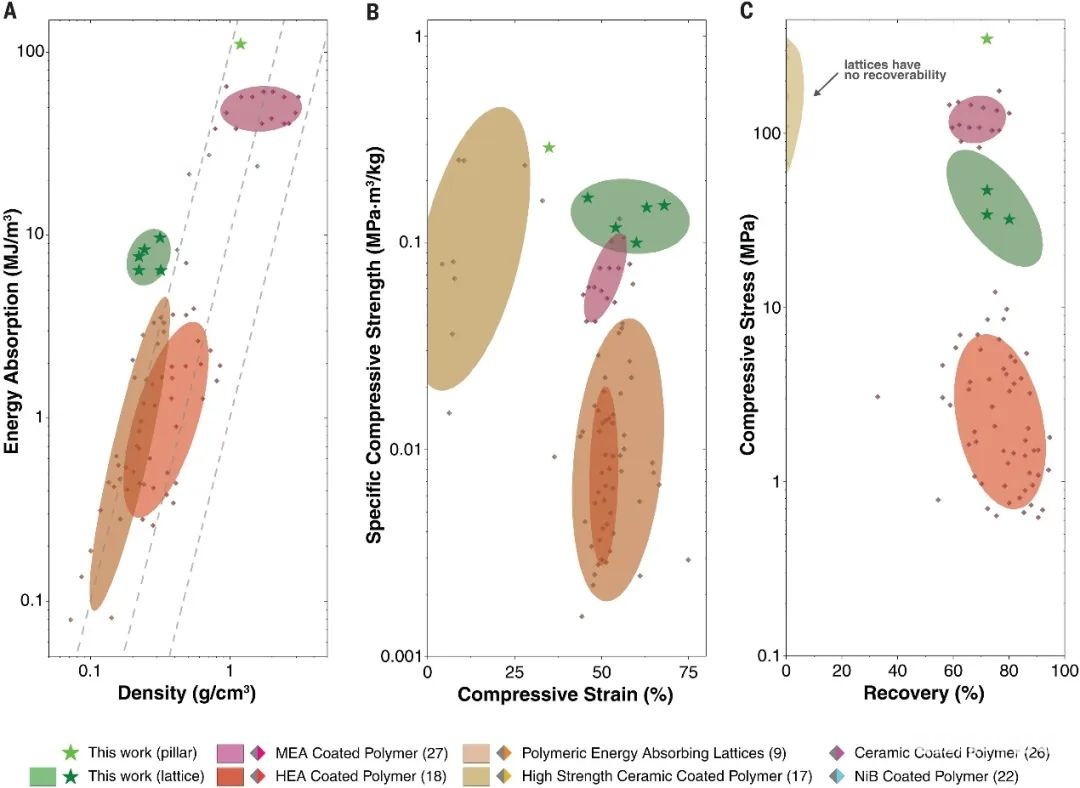

The specific energy absorption of nanoclusters polymer nanolattices and pillars is better than that of polymer microcrystals and nanolattices with inorganic coatings, as well as traditional material systems (Figure 3A). Nanocluster composite materials also have high compressive strength under high strain (Figure 3B) and high recovery ability under high compressive stress (Figure 3C). The glass carbon structure, although having considerable strength and hardness, is not included in this comparison due to its brittle and irreversible behavior. By using nanocluster based photoresists, these mechanical properties can be achieved in a single printing step compared to the multiple manufacturing steps required for core-shell composite grids.

Photoresist based on nanoclusters can be used to manufacture complex nanoporous structures (Figure 4). At a temperature of 900 ℃ under argon gas flow, nanoclusters polymer composites are transformed into glassy carbon with complex nanopore characteristics. Figure 4A shows a nano porous cube printed with 20wt% Ag28Pt photoresist. The average pore size and porosity of the surface of the cube are~56 ± 23 nm and~50%, respectively (Figure 4B). Nanopores extend into the structure~500 to 700nm (Figure 4C) and decrease in size and density further away from the surface. Therefore, the larger structure, as shown in Figure 4D, has a diameter of approximately 8 μ The column of m has graded pores, surrounded by a solid core surrounded by a nanoporous shell. Small structures with a size less than 2 microns are porous throughout the entire structure (Figure 4E). The pyrolytic octagonal lattice has two levels of pores: the geometric design space between the lattice pillars and the nanoclusters induced nanopores within the lattice pillars (Figure 4, F and G). Subsequently, the author developed a nanoclusters protein photoresist. This photoresist utilizes the efficient singlet oxygen generation and significant photothermal effect of metal nanoclusters under excitation. This induces protein photocrosslinking through the oxidation of tyrosine residues (Figure 1B), as well as the formation of directed proteins through local heating β- Flaky crystalline area. A water dispersed Au22 nanocluster was synthesized and used for photoresist. The printing speed of silk cellulose structure can reach up to 100mm/s. The printed protein structure is composed of neatly arranged bundles (Figure 4, H-J), indicating directional self-assembly during the manufacturing process.

Summary: In summary, this work developed photoresists based on metal nanoclusters for manufacturing nanoclusters polymer nanolattices, as well as nano porous glass carbon and protein structures with unprecedented structural complexity. The author indicates that nanoclusters are versatile and efficient two-photon activators suitable for different types of monomers. Nanoclusters polymer nanocrystals exhibit strain hardening behavior, which leads to a combination of high specific energy absorption, specific strength, deformability, and recoverability. Based on this simple and universal framework, by combining hundreds of available metal nanoclusters with different types of monomers and well-designed three-dimensional topological structures, there is a vast opportunity to directly print out more mechanical metamaterials.