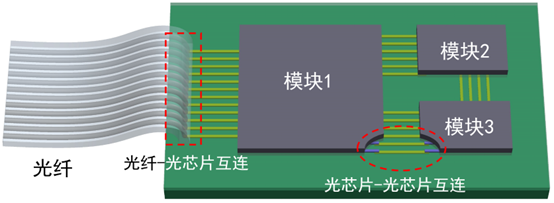

However, there are still key technological bottlenecks in the packaging process of optoelectronic chips. The packaging process of optoelectronic chips, in addition to the well-known interconnection of electrical signals, also needs to consider the coupling of optical signals between different modules, which requires solving the optical interconnection problem between fiber chips and chip chips. There are two main challenges:

1. Optical chips involve multiple material systems and structures, and there are significant differences in the size and distribution of different beam modes. Cleverly solving the problem of mode field mismatch during packaging can achieve efficient coupling between multiple material systems and structures.

2. The beam size in the waveguide on the chip is in the micrometer range, requiring high-precision alignment to achieve efficient coupling, which puts higher demands on the alignment accuracy of the packaging process.

The two-photon lithography technology based on two-photon absorption process, as a three-dimensional printing process in micro and nano sizes, can accurately prepare any three-dimensional structure, which is expected to solve the bottleneck of optoelectronic chip packaging process.

On the one hand, three-dimensional curved surfaces or gradient waveguide structures can be integrated on the chip to shape the beam through reflection or adiabatic compression, achieving ultra wide band mode field transformation;

On the other hand, the morphology of three-dimensional structures has high geometric degrees of freedom, which increases the flexibility of on-chip mode field manipulation, thereby achieving more efficient coupling and interconnection.

In addition, two-photon lithography can also prepare connection structures after sub module assembly, effectively reducing the alignment accuracy requirements during the packaging process.

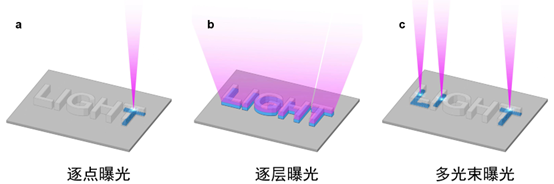

Therefore, in the packaging of optoelectronic chips, two-photon lithography technology has important application value and has been widely explored. Currently, there are mainly three technical routes.

Optical Packaging Method Based on Two Photon Lithography

1. Photon wire bonding

Drawing inspiration from the widely used lead bonding and photon lead bonding technology in microelectronics, a two-photon lithography process is adopted to directly print polymer waveguides between the waveguides to be connected. By gradually changing the waveguide cross-section, adiabatic transformation of the mode field is completed, thereby achieving efficient interconnection between different waveguides. This method has been validated in optical interconnection and coherent communication, and is suitable for various application scenarios such as fiber chip, chip chip, etc.

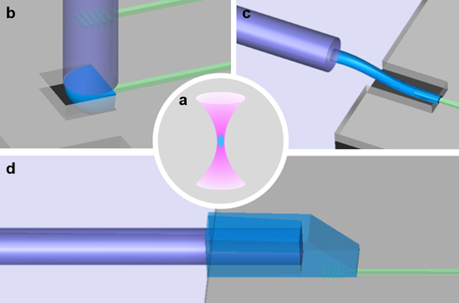

2. Micro Freeform Surface

Print miniature optical free form surfaces on the waveguide end face, shape the outgoing light field of the waveguide in the form of reflection or refraction, regulate the mode field distribution and propagation direction, and thus complete the mode field transformation. The adopted structure has low dispersion, which is beneficial for Wavelength insensitive, it has been verified that ultra wideband coupling from visible near-infrared is compatible with wafer level testing and packaging, enabling high-density interconnect packaging.

3. Mechanical alignment guide structure

Two photon lithography technology can also be used to print mechanical alignment guidance structures, assisting in achieving high-precision alignment during the coupling process. Printing an inverted cone structure on the grating coupling region to guide the alignment process of the fiber can achieve sub micron level alignment accuracy without introducing significant additional losses, and is expected to be applied in pluggable devices.

Exploration of commercialization

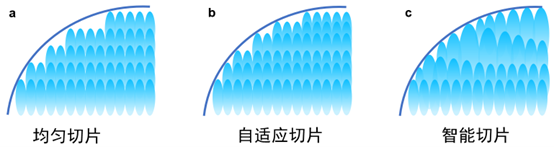

Figure 3: Three slicing methods: uniform slicing, adaptive slicing, and intelligent slicing.

Future outlook

Two photon lithography technology can accurately prepare three-dimensional structures and integrate them onto optoelectronic chips. It can construct a large bandwidth and low loss optical signal link between fiber chips and chip chips, achieve efficient interconnection of optical signals, reduce alignment accuracy in the packaging process, and bring new opportunities to the packaging process of optical chips. With the iterative evolution of technology and further development of the industry, we expect that the optoelectronic chip packaging architecture based on two-photon lithography will be widely applied to solve the packaging problems of optoelectronic chips.